Overhauling wafer ovens according to "SYSTEM 20.000+":

Suitable for:

wafer ovens for flat and hollow wafer, type Haas SWA, SWAK, SWAKI.

The problem:

relatively short maintenance intervalls of about 10.000 working hours on the average, causing hight maintenance costs

and standing hours

The reason:

no suitable possibility to regrease the needle bearings in the locking and hinge system of the baking plates as well as wear in the

selflurbricating bushes of the chain link, locking and hinge systems of the baking chain.

The consequences:

in case of exceeding the service intervalls suggested by the machine manufacturer, the locking and hinge system start moving hard

and harder until blocking. Wear in the selflurbricating bushes of the hinge system reduces the correct guideance and leads to damages

on the sides of the baking plates.

The more economical solution:

overhauling and modification the oven according to "SYSTEM 20.000+" at next service due to the maintenance shedule (10.000 hours).

The idea

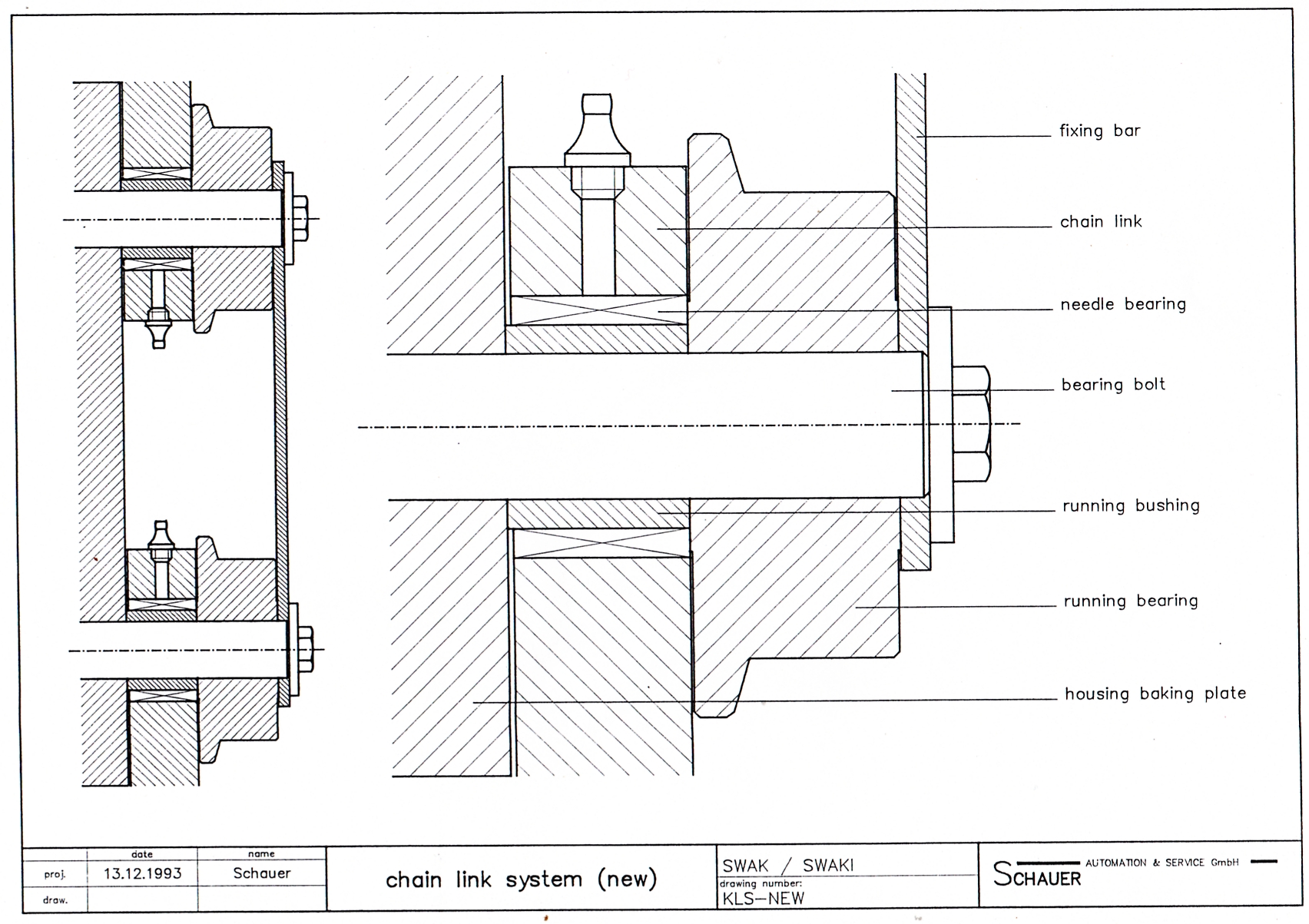

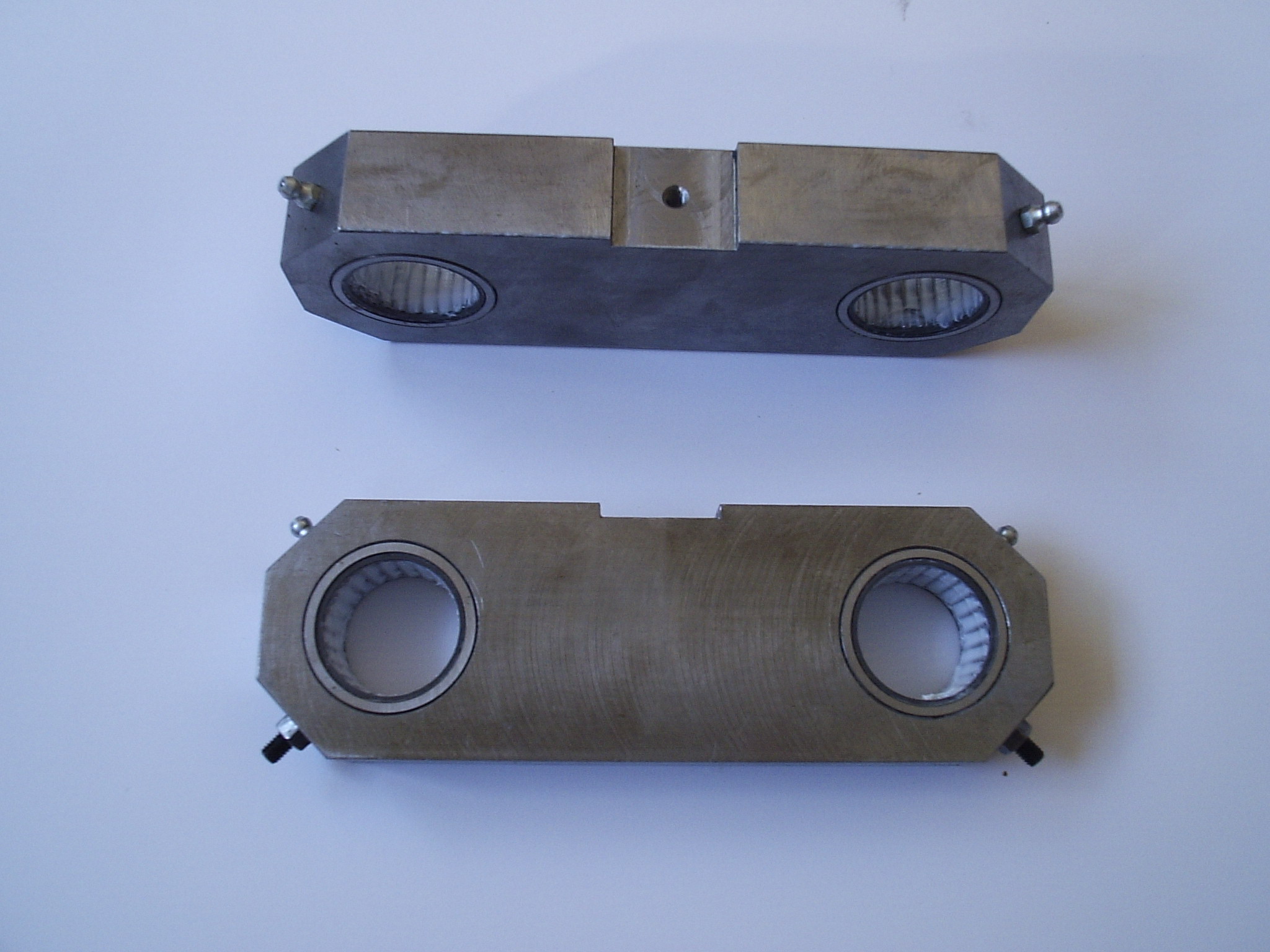

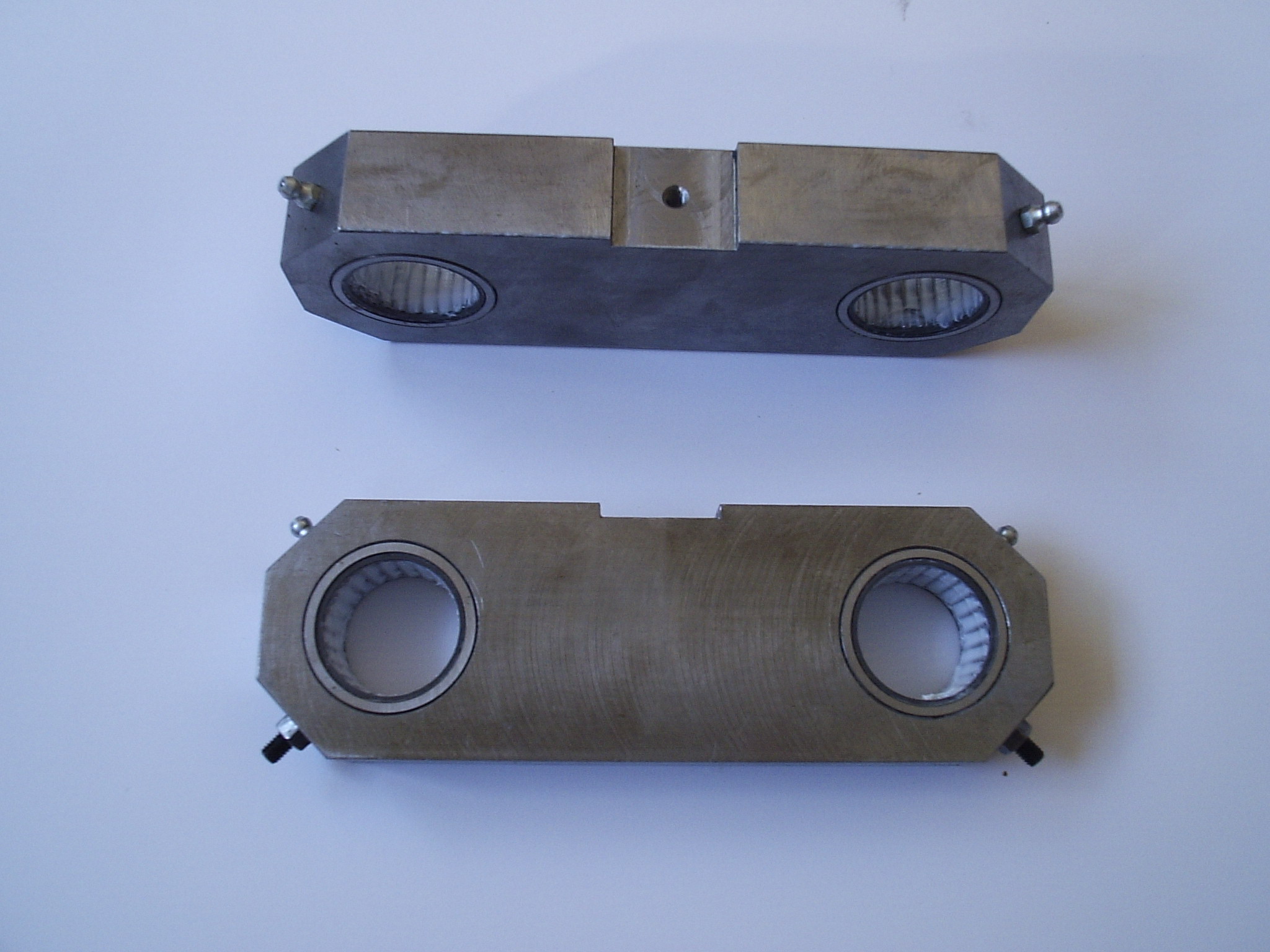

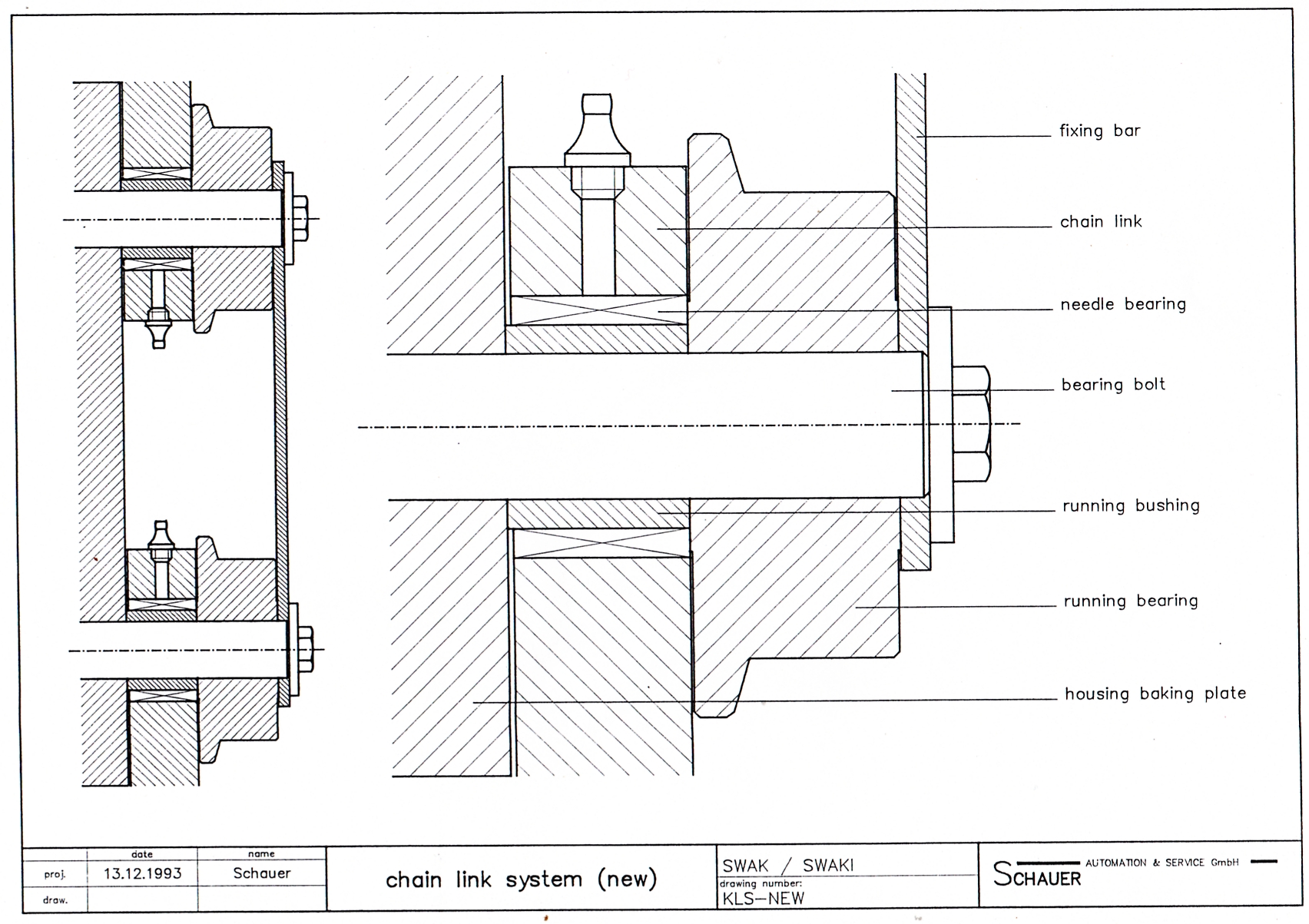

modification of the oven from selflubricating bushes in the chain link, locking and hinge system to needle bushes/bearings as well as

installation of lubrication points in order to achieve regreasability.

The advantage:

increase of service intervalls to clearly over 20.000+ working hours. Related to that the maintenance costs and standing hours

can be reduced considerably

Please find more details in the attached system drawing. If you are in demand for further information do net heistat to contact us.

We should appreciate your inquiry to give you a cost free quotation for the next overhauling of your wafer oven according to our SYSTEM 20.000+"

5. Mechanical Drawing

Back

Privacy Policy